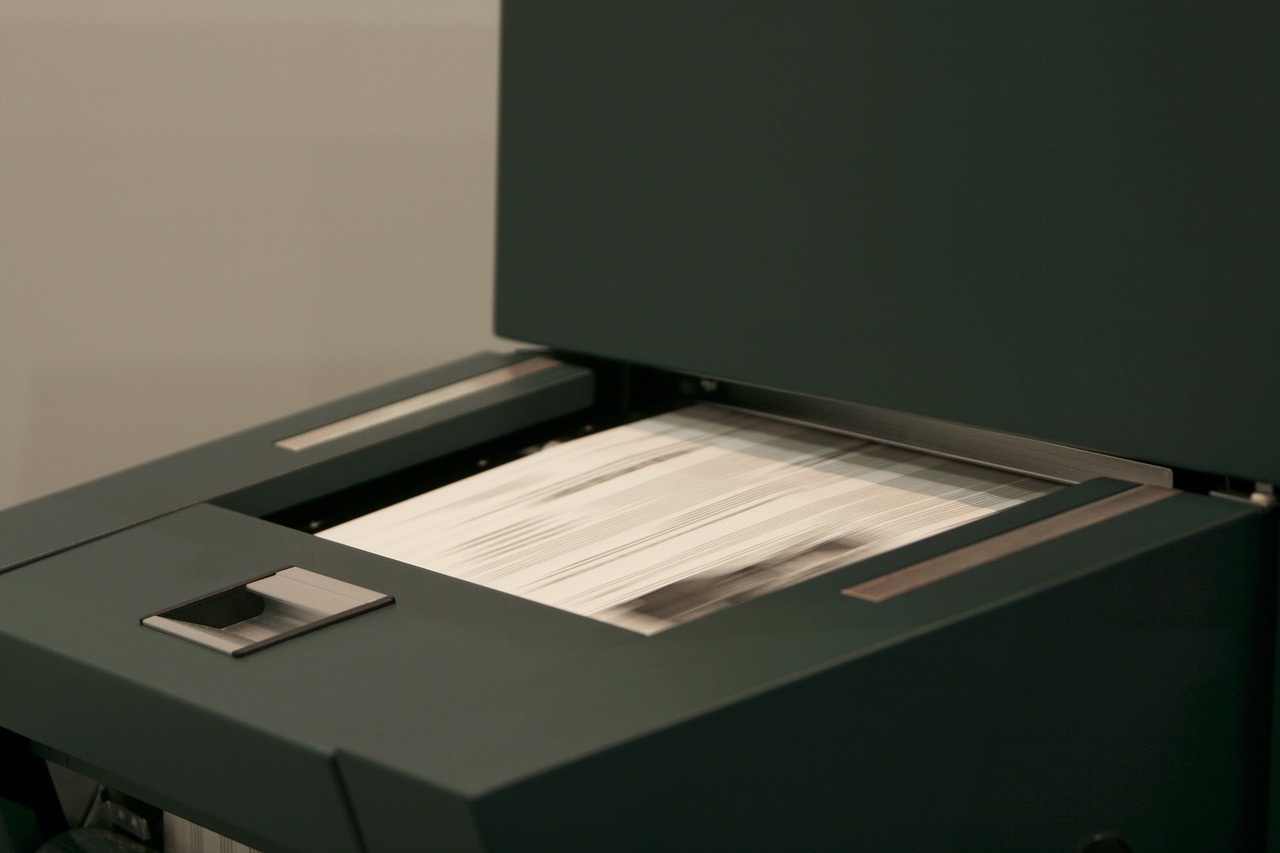

Prepress is the procedure of arranging digital work for a printing press– making them prepared for printing. Business printing companies typically have prepress departments that examine their customers’ electronic files and make changes to them to make them suitable for printing on paper or other substrates.

A few of the common prepress jobs can be carried out by the graphic artist or designer who developed the job, but this isn’t really needed.

Graphic artists generally use crop marks and transform the color modes of their images to prepare for any color shifts, but much of the prepress procedure is managed by skilled operators at industrial printing business utilizing exclusive software applications that are personalized to the business’ particular requirements.

Prepress Tasks in the Digital Era

Prepress jobs differ depending upon file intricacy and printing approach. Prepress operators generally:

– Examine digital files thoroughly to prepare for and remedy any issues that might come up.

– Double-check typefaces to make sure they print properly.

– Make sure graphics remain in the best format and transform RGB files to CMYK, the format used for printing full-color files on a printing press.

– Set the trapping, which is a tiny overlap of particular colors to avoid spaces where the colors touch in a design brought on by minute shifts in the paper as it goes through the press.

– Set the imposition of the file– putting pages in the ideal order for printing. It prevails to print 4, 8, 16 or perhaps more pages on a single big sheet of paper that is later on cut and often folded into a single system.

– Produces digital color proofs.

An experienced prepress service technician at the business printing business best deals with some prepress jobs, such as trapping, imposition, and proofing. There are many wonderful prepress software available in the market, so prepress technology has come a long way in the past years.

Standard Prepress Tasks

In the past, prepress operators photographed camera-ready artwork utilizing big cams, but nearly all files are entirely digital now. Prepress administrators made shading divisions from pictures and included product imprints to documents. The larger part of that is done right away now using select programming applications. Rather of utilizing film to make the metal plates ready for the press, the plates are made from digital files or the files are sent out straight to the press. Much of the hands-on work that conventional prepress professionals carried out is not needed in the digital age. As result of this, work in this field is decreasing.

Prepress Technician Qualities and Requirements

Prepress operators should have the ability to deal with the industry-standard graphics software application consisting of QuarkXPress, Adobe Indesign, Illustrator, Photoshop, Corel Draw, Microsoft Word and other software application that their customers use, consisting of open source programs like Gimp orInkscape.

Some prepress operators are color professionals and make subtle modifications to customer images to improve their look when printed on paper. They have a working understanding of the printing procedure and binding requirements on how they impact each printing task.

An associate degree in printing innovation, electronic prepress operations or graphic arts is the typical entry-level education requirement for prepress professionals. Focus on information and troubleshooting abilities are important as well.