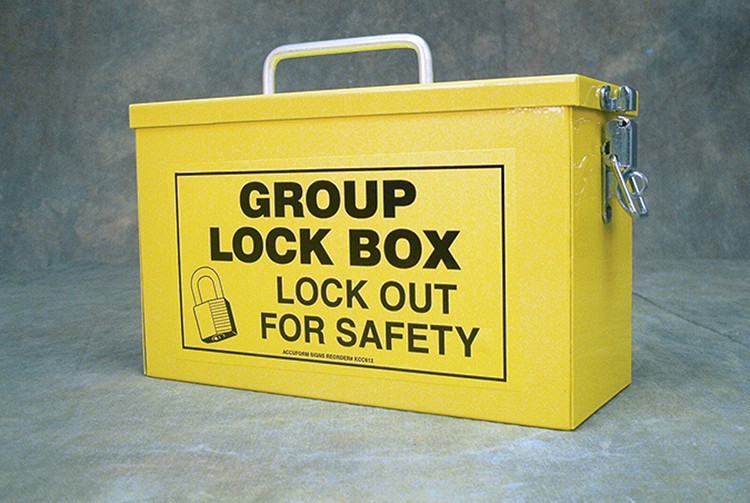

For a long time, group lockout boxes as storage devices have had the capability of capturing keys to effectively lock out large equipment as well as energy sources at workplaces and homes. Several lockout tools and hasps have played a great role in preventing machines under construction or maintenance, from being powered on while a repair is going on or when the machine is out of order. Despite the significant role that electricity plays at workplaces, it has been recognised as a deliberate working hazard. In same cases, events such as electric shocks, explosions and fires burns have occurred. This called for electrical experts to widely borrow safety standards from organisations such as the Occupational Safety and Health Regulation (OSHR) as well as the National Fire Protection Association. OSHR prescribed Lockout/Tagout procedures to enhance secure working environment, which led to the discovery of Lockout boxes which has had profound benefits. These boxes have helped in ways such as:

Lockout boxes restrict access to sources of power during maintenance.

During service work or maintenance of machines, a variety of Lockout boxes has been effectively used to ensure main power switches together with energy sources are locked out and also out of bound. It has helped to avoid accidents during industrial maintenance operations of machines. Multiple padlocks are applied to this boxes where each employee working has to unlock their lock to allow access to the required source.

Lockout boxes avert accidental start-up of machines.

Sometimes during maintenance work on machinery, to interrupt power flow plugs have to be disconnected. To ensure these plugs are not plugged back by mistake, they are locked in power lock boxes. They too function to effectively lock out circuit breakers which eliminate accidental start-up of equipment, a measure that safeguards workers and prevents accidents related to plug sockets.

In some cases, special valves, circuit breakers or other critical devices may not be easily located when doing machinery service or power maintenance. Lockout boxes ensure that lockout is successfully enabled which prevents individuals from initiating any activity that may be risky.

Tracking employees who are still working.

Unlike Hasps, Lockboxes enables you to track who is still working by only checking the group locks on the lock box. Since a lock box only allows one selected employee to be liable of locking out all the devices, it is easy to spot whose lock is not present at a glance since he/she places his keys in the group lock box that all the affected employees must lock. Unlike in hasps where you have to go round checking whose locks are present and missing. In big firms and organisation, this is helpful as it helps identify any employee that is yet done with his/her work. The employee in charge has the mandate to place their lock first and should be the last person obliged to remove it from the group lock box. For instance, during servicing, this employee in charge, is the only one allowed to restore unit back to normal operation.

Lockout frequently initiates check process of equipment.

For regular streamline check process of equipment and effective energy isolation, shock stop group boxes are used. It has a stop sign which draws attention to the workers in case a machine or area under construction is under check or is isolated due to some reasons. They too modify and create instructive maintenance procedures which provide guidelines and instructions to be followed when working with power. It too keeps locks when not in use after the equipment or machine has been checked and verified.