Maintenance is carried out at the installation site of the transformer, without opening and dismantling the bus connecting it to an external power supply, it is a purely preventive repair. It is performed by the repair personnel of the electrical installation operation service.

The scope of the current repair includes:

- external inspection

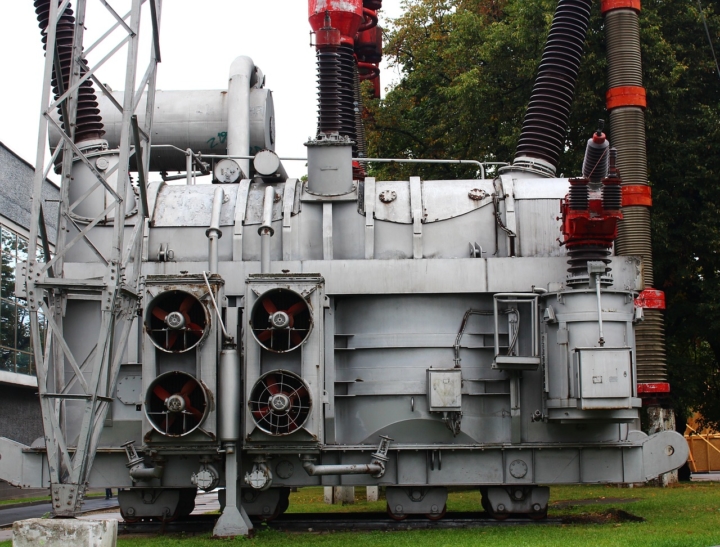

- identification and elimination of minor defects in valves, cooling systems, attachments

- tightening fasteners, eliminating oil leaks and adding oil

Sorbent replacement is in a thermosiphon filter, wiping the outer surfaces from dirt. The measurement of insulation resistance of windings and other minor works are done by Surplec. The duration of such repairs, depending on the power of the transformer, is from several hours to 1-2 days.

Medium repairs, in addition to the work included in the current repair, include opening the transformer with lifting the active part (or the removable part of the tank, if the tank has a lower connector), minor repairs or replacing (if necessary) bushings, bends, switching devices, coolers, oil shutoff valves, oil pumps, fans, etc. It is performed with the disconnection and delivery of the transformer to the repair site.

The Overhauling

Overhauls, in addition to works performed during secondary repairs, include repair of the active part with its disassembly and restoration or replacement of windings and main insulation, sometimes repair of a magnetic system with reinsulation of plates. Overhauls are caused in some cases by damage to the core, windings and insulation as a result of accidents, wear and tear; isolation. At the same time, there are still relatively many domestic and foreign transformers of obsolete designs in the energy sector that are subject to major repairs and reconstruction to increase their reliability and bring the parameters in line with new standards.

The Right Process

To determine the technical condition and the prevention of accidents, the “Rules for Technical Operation” (PTE) of the USSR Ministry of Energy and Electrification provide for scheduled transformer maintenance for transformers supplying the most critical consumers. By tradition, in PTE this type of repair is called capital.

Transformers with voltage of 110 kV and higher and power of 80 mV-A and more and basic auxiliary transformers are to be subject to scheduled preventive maintenance for the first time 12 years after commissioning, and in the future, as necessary, depending on the condition of the transformers and test results, carried out during ongoing repairs. All other transformers are taken out for repair depending on their technical condition and test results. The scope of scheduled preventive maintenance includes opening the transformer, inspection and minor repairs of the active part and its individual devices, mainly: tightening the fasteners, checking the insulation of individual parts of the core, replacing, if necessary, gaskets, wiping, cleaning.

Preparation For Repair

Major repairs of transformers I — IG, partially IV dimensions, as a rule, are carried out in transformer workshops of repair enterprises (plants). Specialized workshops and factories have the necessary production facilities, lifting devices, technological equipment, tools, fixtures and other material and energy resources. In accordance with the technological process, workshops have production sites on which individual assembly units and transformer parts are manufactured and repaired.