In order to serve the growing number of Internet of Things applications, Reflexces has unveiled its new Arria 10 FPGA module (field programmable gate arrays). Reflexces is your one-stop supplier for innovative FPGA solutions. Visit reflexces.com for more details on other products. They are devices designed to perform fast processing and with adequate consumption, to a variety of use cases, such as in the automotive sector, industrial automation, and professional audiovisual and vision systems.

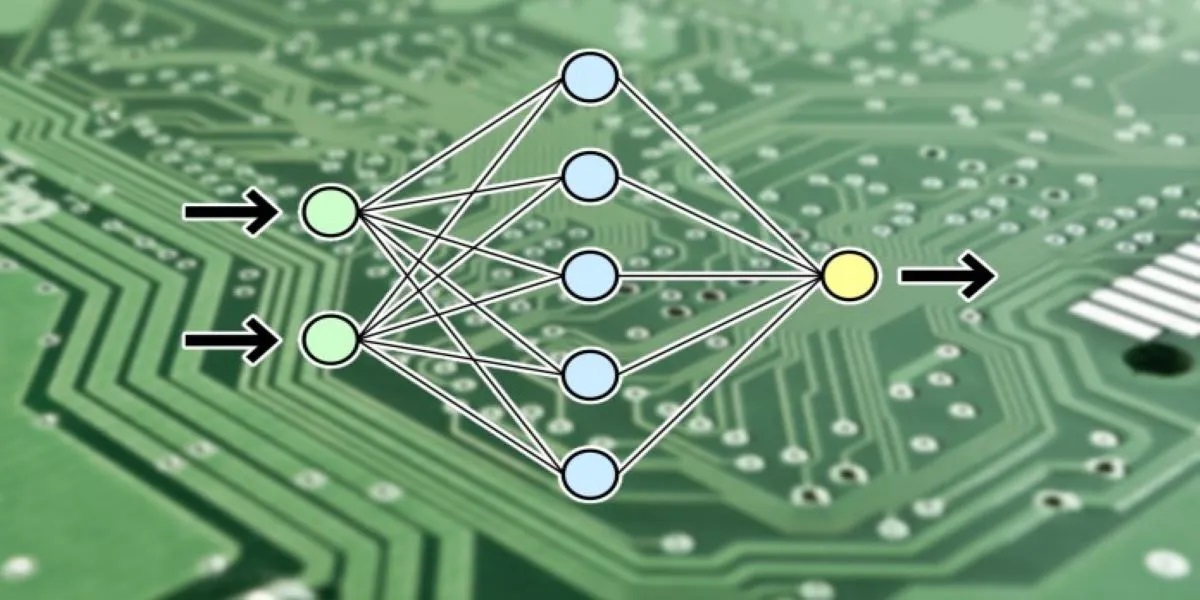

What actually FPGA does in modern industry?

These chips allow the microprocessors or microcontrollers to be downloaded from part of their workload of processing the data from sensors and cameras of the IoT, collecting data, making decisions in real time based on these, and sending them to a destination. Arria 10 SOM FPGA can be programmed to deliver specific computing capabilities and functions required by different IoT applications, while maintaining their unique functionalities to address design needs. These FPGA chips for industrial and automotive applications offer support for transceivers and floating point digital signal processing.

It is easy to program

Architectural innovation in the implementation of IEEE 754 single-precision floating-point digital signal-processing blocks can enable throughput speeds of up to 134 gig floating-point operations per second. It is important for engineers who need higher performance using the FPGA for applications such as motion and motor control systems.

Uses in FPGA for industrial and automotive applications

Applications the Arria 10 SOM fits into include those where high I / O performance and core speed are key requirements, such as computer vision for industrial purposes and smart city applications providing parking surveillance, bridges or roads. It is also a good support for AV applications such as video streaming.

For its part, Arria 10 is aimed at those applications where cost and power are key factors in making design decisions, for example, in cases of video processing in the automotive sector with which it is used in rear view cameras.

FPGA is used to prototype new CPUs and GPUs

FPGA chips are used to test new functionality at the hardware level before implementation in a processor. It means that the functionality is written in a hardware description language such as ‘Very High Speed Integrated Circuit Program Hardware Description Language’ and the FPGA is configured to work like that specific hardware.

Because today the number of logic gates in a processor is several orders of magnitude higher, at the FPGA level, whole cores are not implemented, but units and even parts of them. It is common for the laboratories of large hardware manufacturers and designers to see units such as Cadence’s Protium S-1. They are made up of dozens of FPGA chips. They are connected to each other and allow simulating the operation of more complex processors.

FPGA chip and project simulation

With simulation, we do not refer to being able to execute the programs, as it would be in the final hardware, but to make sure that each of the elements is well interconnected and behaves as expected in the planned design. The simulation via FPGA allows seeing errors in the implementation and then correcting them.