Developing a new tech product is a long endeavor. It would take at least several months even for a simple solution. Many take a lot longer because parts of the process need to be repeated until the item is polished and ready for large-scale manufacturing. To understand why it gets extended, it would be helpful to learn about the steps that make up the entire process. It is a complicated endeavor. In this article, we focus on PCB manufacturing. We’ll discuss how long does it take to manufacture a PCB. This includes the creation of the board itself and the assembly of the components that make up the complete design.

Component Selection and Schematic Circuit Design

Most PCB manufacturers will focus on the creation of the board itself. Interested customers can just send them the relevant files for the parts and design. They will take care of the rest. Some can help customers create the design, as well. In any case, it is important to select the right components because these will have a big impact on the outcome. Refer to the system’s block diagram to get a sense of what you need to accomplish. Figure out which microchips, sensors, displays, and other parts would fit the needs of the project. Develop a schematic circuit design to output a Bill of Materials listing every single electrical component down to the last diode. This whole process can take a few weeks.

Printed Circuit Board Design and Review

Since the schematic diagram is only a conceptual drawing, you will still need to create an actual layout for the PCB. Special software makes this easier but it can still take weeks to complete, especially if the design is complicated with several layers and lots of components. Finding a way to make them all fit in an efficient manner is ideal. Engineers must take their time to ensure that everything is just right. The software can spot issues that require correction. Independent reviewers should also check the work and make suggestions for improvement.

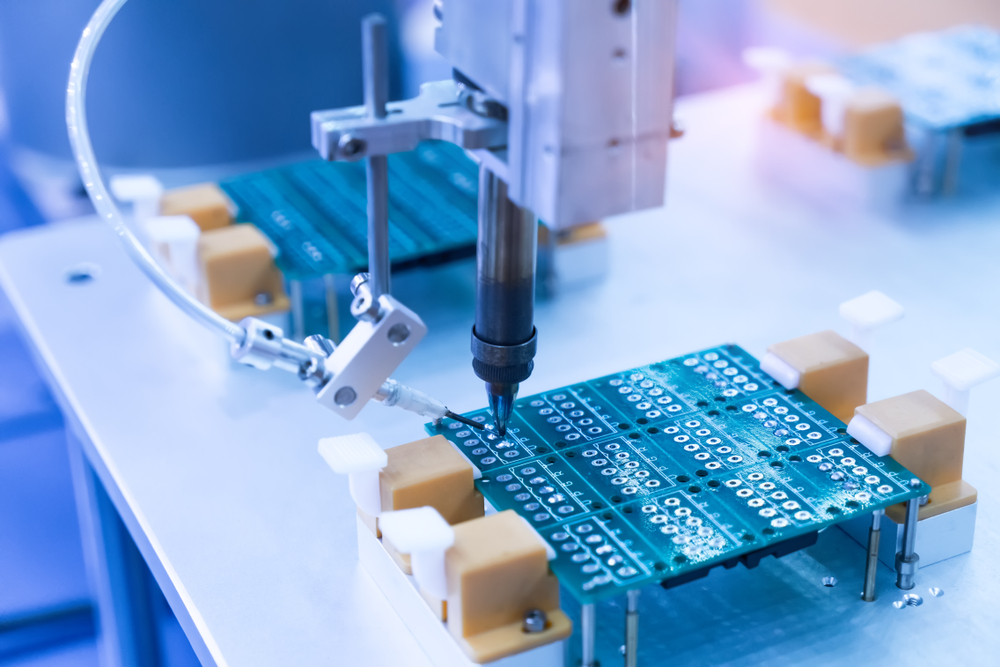

PCB Prototype Manufacturing

Finally, the design files are ready for submission to the PCB manufacturer (we recommend avanticircuits.com!). Just upload these and let the manufacturer do whatever is necessary to print the boards and assemble the components. PCB fabrication takes several days depending on the complexity of the circuit design. If there are many layers, then expect to wait a bit longer. As for the parts assembly, the process can’t start unless the company has all the components needed to proceed. Quantity and complexity may slow this down. Although rare, sometimes there could be component shortages. If everything goes well, then everything should be fully assembled and tested in a matter of days after getting all the materials.

Allow time for the shipment and delivery of the PCBA. Only specialized factories have the necessary equipment to pull this off. These might be located far away, in another state or country. Check the shipping methods available, as well as their time leads. Everything should be transparent at the time of order, so you know just what to expect before you pay.